STEP ONE: RAW MATERIALS

We carry vast stocks of raw materials allowing us to offer a quick turn around on core products.

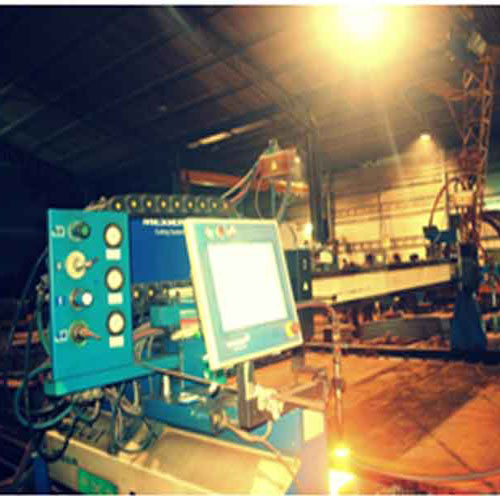

STEP TWO: PROFILE CUTTING

Precision profiles India can perform sheet metal cutting of different sizes and thicknesses, calendering, bevelling and bending using cutting-edge technologies.

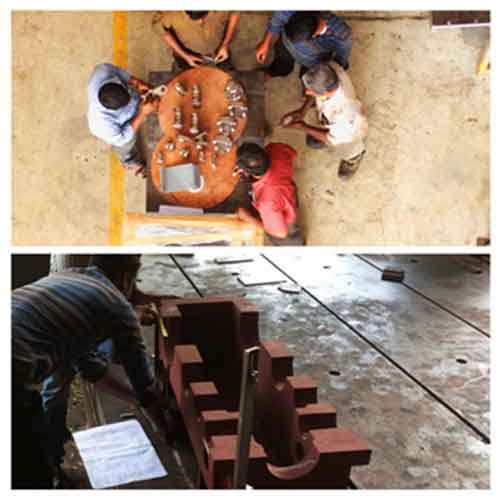

STEP THREE: MATERIAL PREPARATION

Highly skilled workers realize quality products of any size, according to the Customer’s needs. Precision profiles India metal structural works completely satisfy , ISO standards for welding processing. Moreover, they have obtained several certifications that attest the attention towards the operators’ health and the environmental protection.

STEP FOUR: FABRICATION

Fitup the Table process to get into the shape of the given product & Highly skilled workers realize quality products of any size, according to the Customer’s needs.

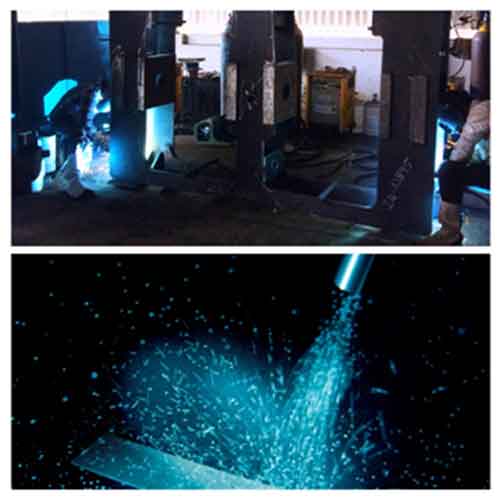

STEP FIVE : WELDING & SHOT BLASTING

Arc coded welding in all disciplines to ensure the highest quality results. Rust and mill skin are two surface contaminants which need to be removed at the shot blasting process to ensure a reliant adhesion of the primer or coating afterwards.

STEP SIX: PAINTING

When you turn to Precision profiles India you know you can rely on a spray painting or powder coating service that – in compliance with the workers’ health and the environmental respect – is performed in

properly equipped buildings using highly usury-resistant and non-toxic paints.

STEP SEVEN: MACHINING

Precision profiles India is able to realize mechanical machining and construction processes of milling and turning of small, medium and big sizes with minimal tolerance limits.

STEP EIGHT: DESPATCH

Products are grouped for shipment, assembled and where applicable hydraulically tested prior to dispatch We organize transport via our own transport facility, pallet service, full or part loads and containers.